VERTICAL AUTOMATIC STORAGE SYSTEM (1000 MAG)

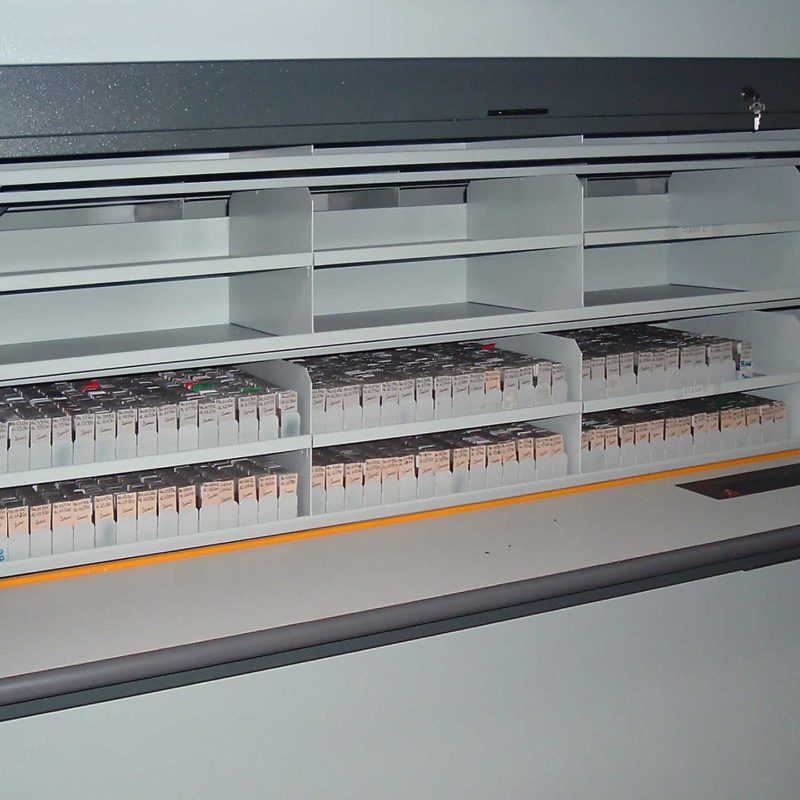

The 1000 Cargo range is engage in warehouse automation of small components like: electronic devices, farmaceutical products, electric engines, small spare parts etc. Faster and easier picking times are importants particularly when the operator needs confort and safety work station. Its vertical configuration saves you space by using the overhead area.

The shelves are made-to-measure and the possibility of modify also the shelves height allows an optimum use of space. The SORGE’s vertical carusel systems can be interfaced with personal computers.

IMPLEMENTATIONS

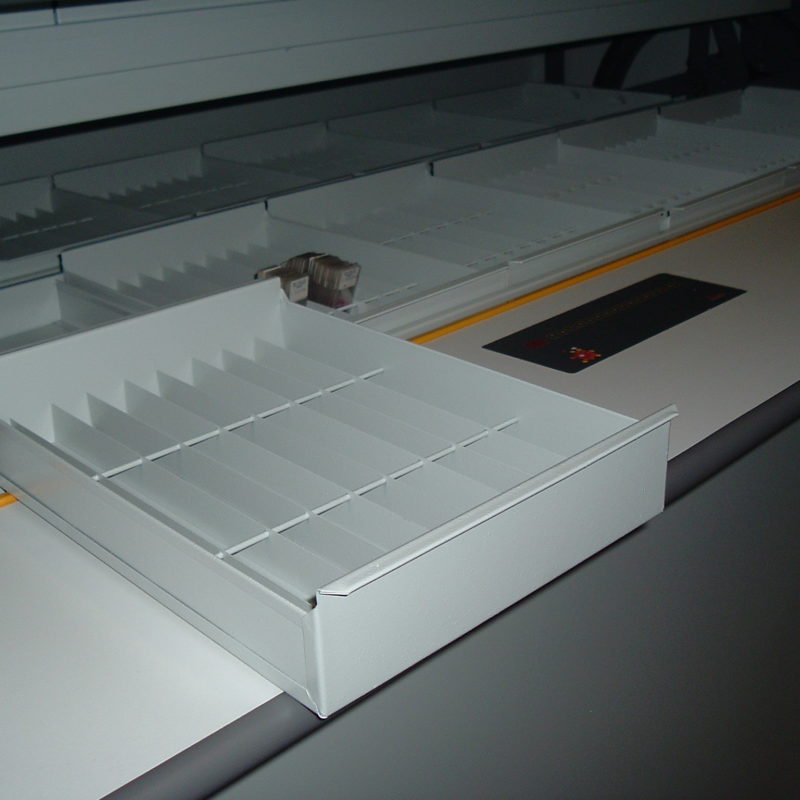

SLIDES

INDUSTRIAL LAUNDRIES

PLASTIC DRAWERS

ELECTRONIC DEVICES

DE ANGELI INSTITUTE

SAFETY AND TECHNOLOGY

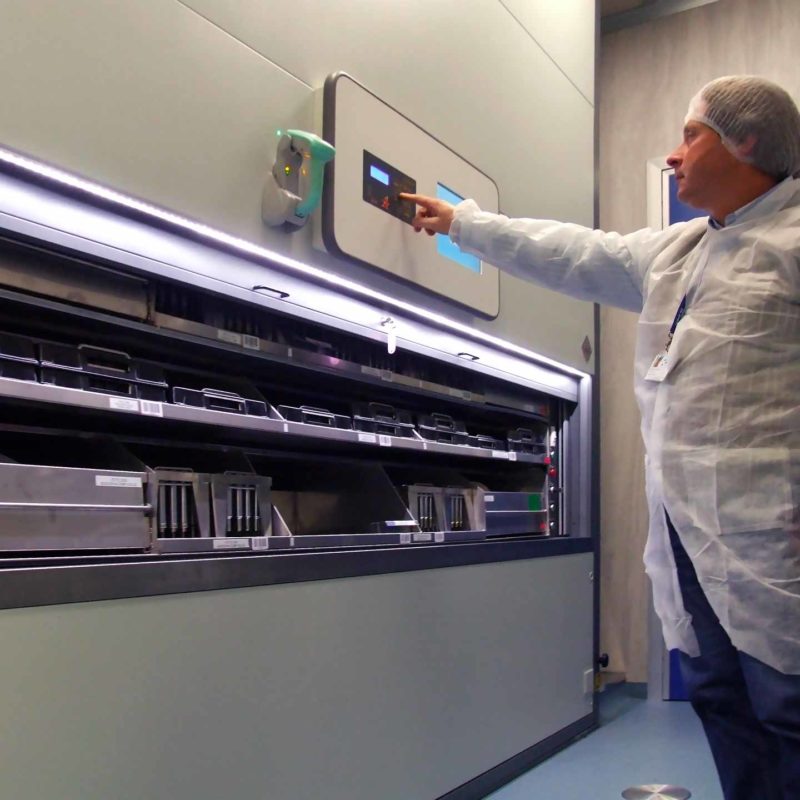

The keyboard can be set with an access code function and is equipped with MULTICOLOR LEDS SYSTEM TO CHECK UNBALANCING LEVEL.

WORKING MODE:

- Simple shelf call up The operator push the number of the selected shelf and then push ENTER. The automatic filling system start the movement. Electtronic control system ensures that the shelves selected always take the shortest route to the work desk.

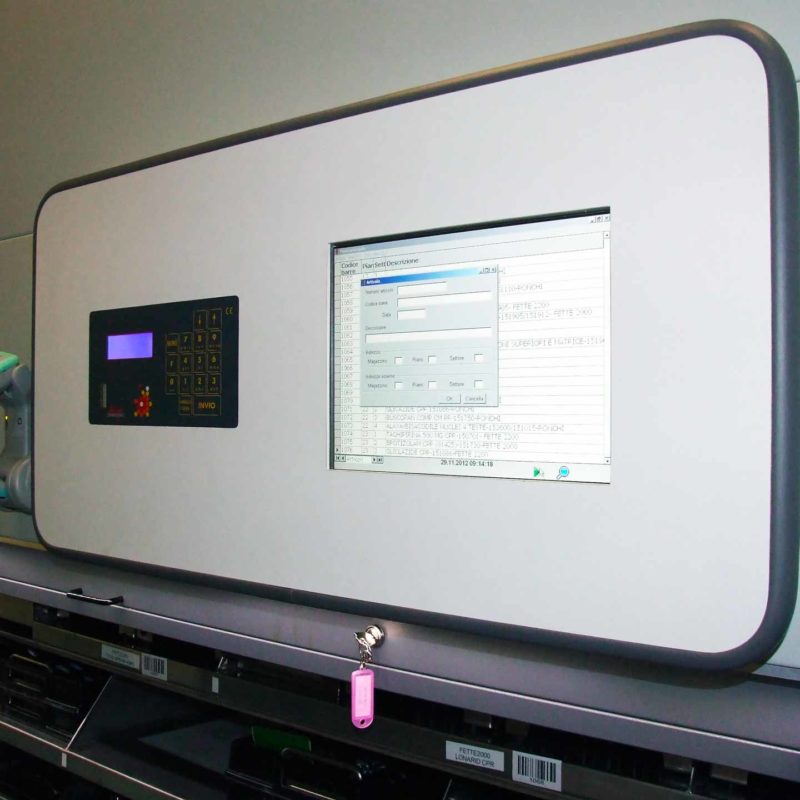

- Remote control when the archives is connected to a host computer the system is working in the remote mode. The link is made by an RS232C interface. In remote mode the commands are set by the computer according to internal software.

The 1000 range conform to the security principles set out in EEC “Directive on Machinery” 2006/42/CE and therefore bears the CE standard mark:

- Litghting push button for emergency stop

- Electrical interblock on emergency handling to avoid dangerous restarting on unexpexted voltage return.

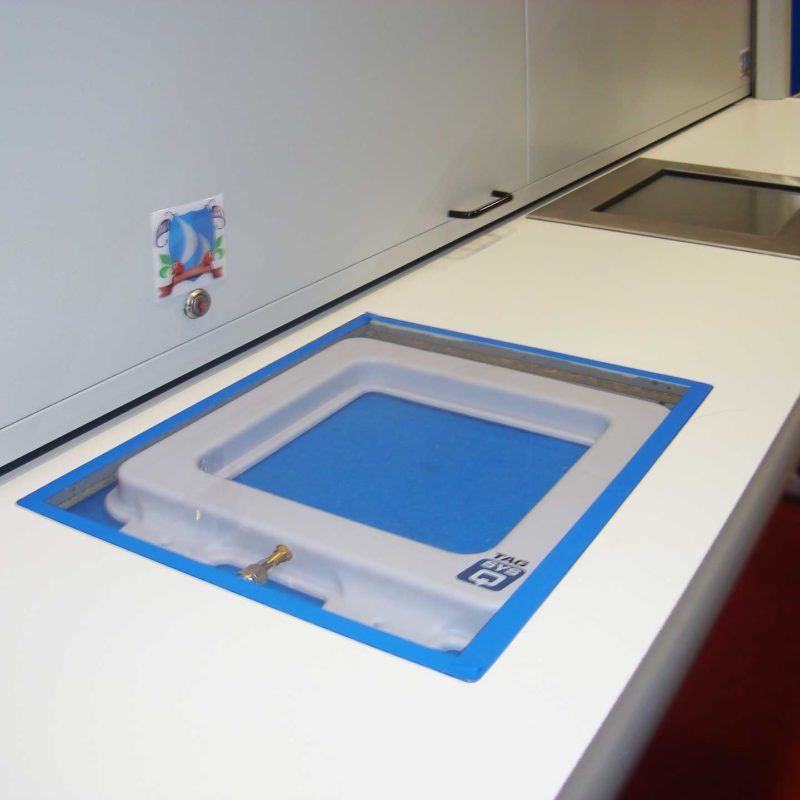

- Optoelectronic barriers in the lower and upper operating area to stop immediately the movement in case of obstacles.

- Mechanical devices in the lower and upper operating opening with the same function of previous ones.

Vertical archives can be equipped with a fire detection and extinguishing system

AUTOMATIC FILING SYSTEM WITH ROTATING SHELVES (700 RANGE)

The 700 range main feature is that the operator has the documents at his fingertips without open any record cards drower.

Thanks to the small and compact dimensions of the body these filing systems fit in with any deco and represent an excelent solution to stock middle volumes of cards and frontal hanging files.

IMPLEMENTATIONS

SLIDES SERIES 700

INDUSTRIAL LAUNDRIES SERIES 700

SAFETY AND TECHNOLOGY

The keyboard can be set with an access code function and is equipped with MULTICOLOR LEDS SYSTEM TO CHECK UNBALANCING LEVEL.

WORKING MODE:

- Simple shelf call up

The operator push the number of the selected shelf and then push ENTER. The automatic filling system start the movement. Electtronic control system ensures that the shelves selected always take the shortest route to the work desk.

- Remote control when the archives is connected to a host computer the system is working in the remote mode.

The link is made by an RS232C interface. In remote mode the commands are set by the computer according to internal software.

SAFETY FEATURE INCLUDE:

- Litghting push button for emergency stop

- Electrical interblock on emergency handling to avoid dangerous restarting on unexpexted voltage return.

- Optoelectronic barriers in the lower and upper operating area to stop immediately the movement in case of obstacles.

- Mechanical devices in the lower and upper operating opening with the same function of previous ones.

The 700 range conform to the security principles set out in EEC “Directive on Machinery 2006/42/CE” and therefore bears the CE standard mark.